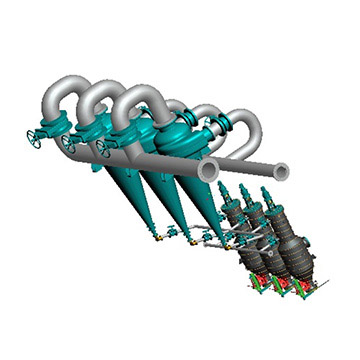

In the residue oil cyclonic filtration system, the material goes downward with spiral movement via the cyclone, with the action of inertia centrifugal force, coke particles are thrown to the outer wall, with the down swirling flow to the bottom of the cone outlet, because the specific gravity of coke particles is greater than quench oil, the coke particles are drawn to the outer edge of the cyclone. The filtered quenching oil is at the center of the cyclone, which is inducted from the central tube of the cyclone and into the filter via the cyclone outlet. After filtration by the Johnson Screen(with many precision options), the cleaned quench oil flows back to the quench tower via the filter outlet. Coke particles adhering to Johnson Screen become filter cake. When filter cake reached a certain thickness, it will generate a pressure drop and reduce the flow rate, as the concentration of coke in sticky quenching oil particles entering the filter is very high, the automatic filter cake removal without shutdown is very essential.

In our design, when the pressure drop reaches 0.05 MPa, the process for filter cake removal will be started automatically, or the continuous cake removal could be set normally open. Our quench oil cyclone plus filter system is advanced, high precision, convenient, reliable, less maintenance, no clogging problems, fully in compliance with HSE.